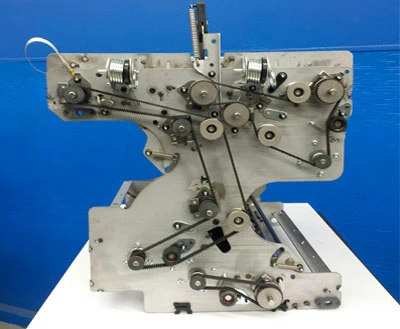

Any system, device, or product that incorporates electricity, circuitry, and mechanical components to perform a function is an electro-mechanical assembly. They vary in size and complexity, but usually include similar elements like motors, wires or cable, switches, actuators, or power supplies. Typically, the electrical components power mechanical parts or subassemblies. A completed assembly may be contained in an enclosure or added to another larger assembly.

ACRO Industries, Inc. provides expert electro-mechanical assembly and subassembly services for use in a range of applications. Learn more about our process, different types of assemblies, and the industries we serve.

The Electro-Mechanical Assembly Process

Because each electro-mechanical product or subassembly is designed to carry out a specific task or function, we start by learning its underlying goals and design intent. This is especially the case when an assembly will be integrated into a larger product or assembly.

The process begins with a review of the application’s functional requirements, including operating conditions, space limitations, and safety requirements. Specifications including materials, dimensions, and tolerances are also critical, and these should be designated in blueprints and schematics of circuitry and components. Some products can be assembled under standard manufacturing conditions, while others require assembly in a controlled or cleanroom environment.

A bill of materials (BOM) that outlines the components to be used, along with a wire run list, and other documentation are created prior to building a prototype and testing. A breadboard may be assembled to test the placement and operation of electrical components, chips, and wires, prior to soldering on a PCB or permanently attaching anything in an enclosure.

Assembly can be performed manually by a skilled operator, by automated equipment (e.g., robotic arms for soldering, pick-and-place operations, or verification/inspection), or a combination.

Quality control measures include visual inspection, functional testing, and verifying electrical output of the system. The assembly process or components may be refined or adjusted if errors or potential points of failure are discovered at any point in the electro-mechanical assembly process.

Types of Electro-Mechanical Assemblies

While each application is unique, most assemblies contain similar components like motors, gears, sensors, power supplies, switches, solenoids, mounting hardware, wires and cable, insulating materials, chips, and electronic components. They fall into general types, including but not limited to:

- Switch and Sensor Assemblies: Switches control the flow of electrical current to and from the switch to supply power to other components. Sensors detect stimuli like motion, light, temperature, and pressure and create a signal to supply power to other components.

- Power Supply Assemblies: Power supply assemblies use elements like transformers, filters, rectifiers, or regulators to convert current into the correct voltage to supply power to a mechanism.

- Panel Assemblies: Electrical assemblies integrated into panels typically control the distribution of electrical power into connected circuits. Assembly requires positioning each component in the correct location and wiring the panel.

- DIN Rail Assemblies: Some assemblies require additional physical support to position components. DIN (i.e., Deutsche Institut fur Normung, or German Institute for Standards) rails are specialized metal bars designed to mechanically secure and support equipment in place in electrical cabinets, racks, and other enclosures.

- Transformer Assemblies: These transfer electrical energy between two or more electrical circuits, by increasing or decreasing the voltage.

Industries That Use Electro-Mechanical Assemblies

Electro-mechanical assemblies are widely used in industrial, commercial, and consumer products and applications. The experienced team of engineers and experienced electro-mechanical assemblers make ACRO a leading provider of expert design, assembly and box building, and testing for the following industries:

Business Machines

These include machines commonly used in offices, stores, and public spaces including self-serve electronic kiosks, self-checkouts, ATMs, photocopiers, and printing equipment.

Aerospace

Aircraft require compact, high-precision electromechanical assemblies including junction boxes, switch panels, power boxes, cockpit panels, sensor assemblies, and high-power connectors.

Agriculture

Agricultural equipment like tractors and sprayers contain electromechanical assemblies such as switches, sensors, and actuators for power and motion control.

Heavy Equipment

Assemblies used in heavy equipment and vehicles require extra protection from harsh climates, temperatures, shock, and vibration. This may include water-tight or fireproof enclosures, heavy-duty insulation, robust brackets, or specialized materials.

Military

Military applications must often meet specific standards for materials, design, and durability in extreme conditions. Assemblies may include extra-rugged wire and cable harnesses; water-, fire-, or explosion-proof enclosures; or even cleanroom assembly to eliminate contamination risk for highly sensitive circuitry.