At Acro Industries, Inc., our priority is helping you find the best product for your needs and budget. Our laminate panels provide an ideal solution for applications that require strength or corrosion resistance while keeping costs and overall product weight to a minimum. Customizable per your particular requirements, our team will design and manufacture durable industrial panels to suit your expectations for form and function.

About Industrial Custom Laminating

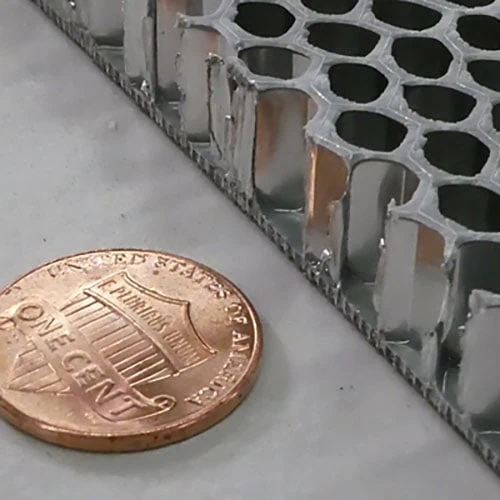

By bonding at least two layers of different materials together, our laminating process results in the creation of a new composite with enhanced properties. For example, while we can simply apply an adhesive film with this industrial technique, we can also achieve a panel with an improved strength-to-weight ratio, better resistance to wear or heat, and enhanced surface protection.

Laminating utilizes either cold pressure and an adhesive or heat to join material layers. Common materials include such options as aluminum honeycomb, steel, plastic film, wood, and foam. The process is highly versatile, making it ideal for applications ranging from railway components, recreational vehicles, truck market, marine applications to healthcare devices and laboratory medical equipment.

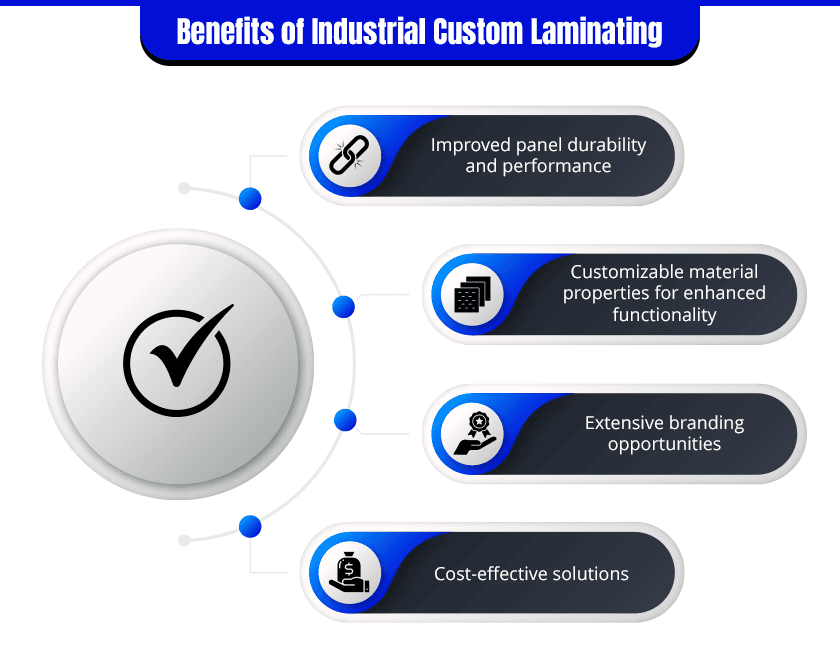

Benefits of Industrial Custom Laminating

Choosing industrial custom laminating for your panels enables you to optimize your products for your specific needs. The process delivers the following advantages:

- Improved panel durability and performance. With custom lamination, you increase the strength and durability of your panels to better support their lasting performance.

- Customizable material properties for enhanced functionality. You can improve panel functionality with custom laminating as well, selecting materials that will best safeguard against abrasion, corrosion, moisture, heat, UV light, and more in your unique application.

- Extensive branding opportunities. The industrial custom lamination process also allows us to use graphic design to make your laminate panels stand out and highlight your brand.

- Cost-effective solutions. Acro Industries is committed to offering our customers quality products at competitive rates. Also, with our industrial custom laminating and production processes, we make the most of your materials to reduce scrap waste and overall product weight to approve energy efficiencies.

Types of Laminate Panels We Produce

At Acro Industries, we serve a diverse client base with our strong, lightweight flat and curved panels. Our experienced team manufactures custom laminate panels for customers in markets such as aerospace, marine, transportation, railways, and recreation. The intended applications for our panels include, but are not limited to the following:

- Access panels

- Windscreens

- Ceilings and walls

- Structural wall and floor components

- Door pocket assemblies

- Enclosures

- Cosmetic interior assemblies

- Climate control panels

The Acro team can custom laminate panels that are as large as 165 inches long and 63 inches wide. We not only make panels, but the final assembly of a panel with extrusions, inserts, doors, handles, locks, and latches. Acro Industries utilizes most of the primary computer-aided design (CAD) formats to manufacture our panels, with options including AutoCAD, SolidWorks, and CATIA.

Our products are made to order. Along with material choice, you can select the thickness of the bonded material and honeycomb, cell size, and skin finish. We can also edge fill, as needed. Ultimately, our team can make material, adhesive, and design optimization suggestions to help you develop high-quality panels tailored to your needs.

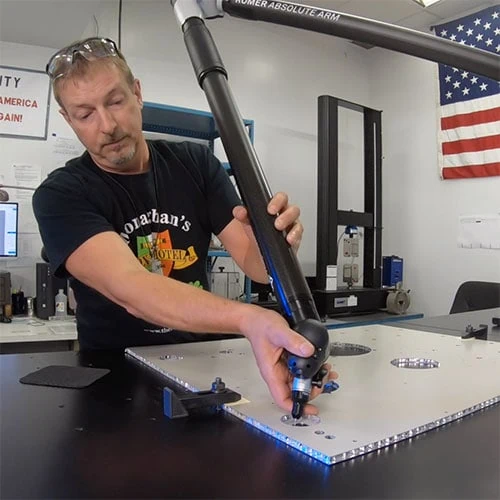

Acro Industries prioritizes quality and customer satisfaction in everything we do. We’re always looking for ways to boost process efficiency and drive out costs for our clients. Our experts can also ensure compliance with your desired specifications, such as Mil-Spec, ISO 9002, and AS9100 standards. We conduct all laminate panel testing in-house including pull test measuring and drum peel.